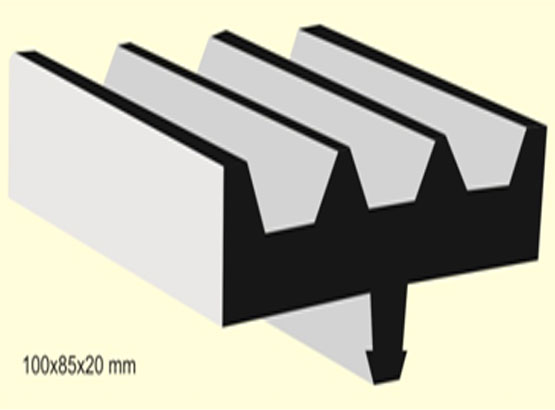

EPDM Rubber Pad

S No. |

PROPERTIES |

Test method |

Spec |

|

Base polymer |

|

EPDM |

1 |

Hardness (Sh.A) |

ASTM D2240 |

80±5 |

2 |

Tensile Strength (MPa) min. |

ASTM D412 |

12 |

3 |

Elongation@ Break (%) min. |

|

200 |

4 |

Heat Ageing@ 70°C/70 Hrs |

|

|

|

Change In Hardness, (Points), max. |

ATM D573 |

+10 |

|

Change In Tensile (%), max. |

|

-25 |

|

Change In Elongation (%), max. |

|

-25 |

5 |

Compression Set @ 70°C/22 Hrs (%) max. |

ASTM D 395 Method B |

35 |

6 |

Resistance to Ozone,Quality |

ASTM D 1771 |

85 |

7 |

Water resistance for 70Hrs/100°C, |

ASTM D 471 |

10 |

8 |

Colour |

|

Black |

9 |

Density |

|

1.19±0.03 |

10 |

Tear Strength daN/cm |

|

38 |

11 |

Max. Ash Content |

|

<5% |